What Is Tensile Test in Welding

The tensile strength weld testing is typically used to measure the strength of a welded joint. The current edition includes two new annexes C and D which address tensile testing of narrow groove.

Physical Weld Testing Destructive Nondestructive Weld Guru

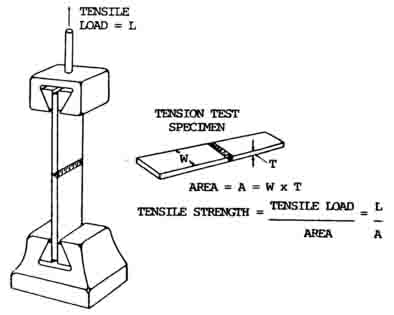

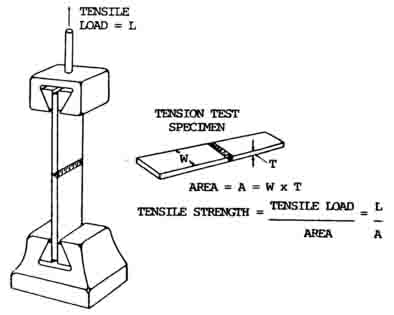

In order to verify the required mechanical properties of a material a tensile test can be performed.

. The seventh edition included three new weldability tests WIC trough and GBOP and resistance weld tests. Therefore the result of the Tension Test will have Acceptance Criteria as. It measures the force required to break a composite or plastic specimen and the extent to which the specimen stretches or elongates to that breaking point.

Tensile Strength Ultimate tensile strength UTS often shortened to tensile strength TS or ultimate strength12 is the maximum stress that a material can withstand while being stretched or pulled before failing or breaking. The amount of tensile stress that a material can withstand before it experiences plastic deformation. A sample of specified dimensions is loaded in tension until the point of failure.

This test provides information about the tensile strength yield strength and ductility of the metallic material. Hardness testing and stud weld tests and organized the tests by weld type. A segment of the to be tested the welded plate is to place the weld midway in the jaws of the testing machine.

Tensile testing is a crucial step in understanding weld performance and ensuring that a finished weld is as strong or stronger than the base metal. Tensile testing also known as Tension Test is a destructive test method and the most common type of mechanical test. So to have a WPS accepted based on the tensile test the following conditions have to be met.

Tensile strength is defined as a stress which is measured as force per unit area. A non-destructive stainless steel pipe welding test or multiple tests can also be used on weldments. During the test elongation of gauge length marked initially are measure by load dial.

Usually bend tests are designed so that the outer surface of the specimen is stretched to a ductility level that approximates the minimum percent elongation required in a tensile test. Two end of specimen is held in a tensile testing machine and load is applied on it. To approve a butt welding procedure most specifications such as ISO 15614 and ASME IX require tensile tests to be carried out.

Tension Test which is the test of the strength of the weld by The principle of ASME is that Weld Metal must be stronger than or equal to the strength of Base Metal. It is used to find out how strong a material is and also how much it can be stretched before it breaks. The test specimen will be subjected to a slowly increasing tensile force until fracture occurs.

The questions are exam-oriented. Tensile Testing is a form of tension testing and is a destructive engineering and materials science test whereby controlled tension is applied to a sample until it fully fails. Tensile test is the drawing of materials until they break under constant temperature in order to determine the strength properties under static non-impact load and to obtain the Stress-Strain diagram during this process.

Fracture Toughness the ability of a metal to absorb energy in the presence of a sharp notch often when subjected to an impact load. Transverse Tensile Test at Welding. This is used to find tensile strength and ductility properties of the weld.

Longitudinal Tensile Test in Welding Tensile test is the drawing of materials until they break under constant temperature in order to determine the strength properties under static non-impact load and to obtain the Stress-Strain diagram during this process. This is one of the most common mechanical testing techniques. Quantitative values associated with a tensile test a bend test will demonstrate both the quality of the weld and its overall ductility.

Among the test are tension and bend tests made on specimens of a certain shape and dimensions. Tensile Strength measure of the maximum stress that a metal can support before fracture begins. Name the property that is determined by using the offset method.

Tensile tests on base material. Students can also learn these welding questions and answers for other welding tests. Tensile testing of all metal and composite materials bolts and welded joints in our laboratory is carried out under.

This easy-to-perform assessment provides a wealth of information that is critical for selecting the best filler metal for an application. Tension Test or Tensile Test shall demonstrate that the deposited weld is stronger than or equal to the base metal strength. CWI Exam Metal Properties and Destructive Testing 1.

The tensile physical weld testing sample is then mounted in a machine to yank it with enough force that it can break the specimen. For several applications we probably want these three to be as high as possible. These are generally cross joint CJ tensile tests of square or rectangular cross section that as the name suggests are oriented across the weld so that both parent metals both heat affected zones.

The width and thickness of the test sample are measured before the testing. Tensile strength is a destructive testing method that demonstrates the maximum stress a material withstands before failing or breaking. The following are CWI exam questions and answers.

The tensile strength test is designed to test the strength of the welded joint. Tensile testing is a destructive test process that provides information about the tensile strength yield strength and ductility of the metallic material. After completion of the test it is possible to determine various mechanical properties of the material like.

Click here to Learn How to write a WPS or a. Pulling or stretching the material to its breaking point is how tensile strength is calculated. Before testing you have to take the test specimen measure its width thickness and calculate the area in square inches.

Tensile testing is a destructive testing method that is done early when testing weld performance. Welding procedure approval for tensile testing. The sixth edition 1998 added six new weld-ability tests.

Testing of welds is used to verify that the welding procedure is under control. I Hardness ii Tensile Strength iii Yield Strength. Weld testing even if not required by specifications helps welders to check and improve their own technique.

When welding to code the requirements will include specifics about tensile testing but even operations that arent welding to code can benefit from this testing data to guide cost-effective and safe part design.

What Is Weld Tensile Testing And Why Is It Important Fabricating And Metalworking

Hobart Brothers Company Weld Tensile Test Overview Youtube

Physical Testing Welding Positions Welding Machines And Other Weliding Cutting Systems Plasma Welding

Tensile Test A All Weld Metal In Longitudinal Direction B Dimension Download Scientific Diagram

No comments for "What Is Tensile Test in Welding"

Post a Comment